The electromagnetic pump consists of an electromagnetic valve, a pressure plunger device, a one-way valve device, an oil inlet device, and an oil outlet device. The working principle is mainly divided into oil pressure stroke and oil suction stroke. During the oil pressure stroke, the solenoid valve is powered to drive the oil pressure plunger to pressure the oil, the oil inlet is closed, the one-way valve device is opened, and the pressure oil is discharged through the oil outlet; During the oil suction stroke, the solenoid valve loses power, and the reset spring in the oil pressure plunger device causes the plunger to reset. At the same time, the one-way valve device closes and the oil inlet opens to replenish oil.

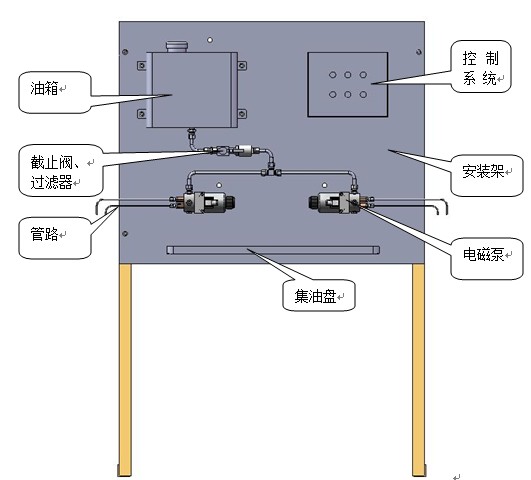

The electromagnetic pump system consists of several parts, including the fuel tank, control system, mounting bracket, pipeline, shut-off valve filter, electromagnetic pump, and oil collection pan. The fuel tank contains the oil required for the operation of the electromagnetic pump, and the amount of oil needs to be added at regular intervals according to the usage. The stop valve filter and pipeline cooperate to form a pathway connecting the oil tank and the electromagnetic pump. The control system controls the movement of the electromagnetic pump and alerts for low oil levels. The oil collection tray is responsible for collecting the oil that drips during system operation or maintenance, and maintaining the cleanliness of the site. All the above items need to be installed on the mounting bracket, which is fixed to the ground near the equipment that needs lubrication and directly connected to the lubrication point through pipelines. This is the working principle of the electromagnetic pump lubrication system.

中文

中文 英语|English

英语|English 法语|France

法语|France 印度语|San

印度语|San