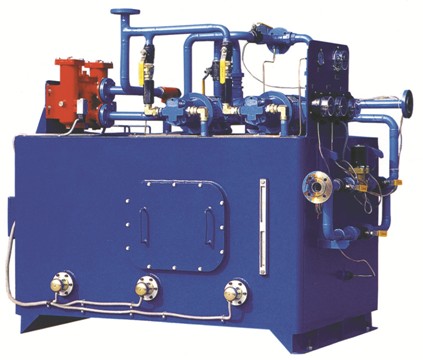

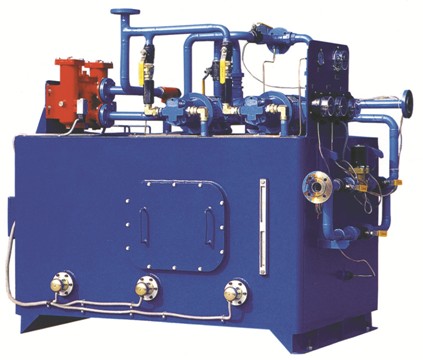

This product is suitable for rare lubrication circulation systems, with working media including turbine oil, 20-25 grade mechanical oil, and rolling mill oil, and a kinematic viscosity grade of N22-N460.

The nominal oil supply pressure of the lubrication station is 0.4 MPa. The filtration accuracy is 0.08mm-0.12mm; The inlet oil temperature of the heat exchanger is 50 degrees, and the temperature is reduced by 7-8 degrees; When using steam heating, the steam pressure is 0.2-0.4 MPa. Cooling water temperature ≤ 20 degrees; The cooling water pressure is 0.2-0.3MPa.

Structural characteristics

Equipped with a main oil pump and a backup oil pump, it can ensure continuous oil supply to the main engine.

Placing the filter before the cooler can improve the filtering and passing capacity.

Adopting a dual tube filter, the filter element can be cleaned and replaced without stopping.

Adopting a tubular oil cooler, it has good cooling effect, low resistance, and is easy to maintain.

The return oil is equipped with a magnetic filter that can adsorb and remove iron foam particles from the oil, ensuring the cleanliness of the oil.

Equipped with an instrument panel and an electrical control box, it is convenient to observe operating parameters and can achieve automatic control and accident alarm.

The centralized lubrication system has obvious advantages because there is sufficient supply of pressure oil, which can ensure that a large number of widely distributed lubrication points are lubricated in a timely manner, and at the same time, the friction heat generated by the friction pair is carried away; Metal abrasive particles and other mechanical impurities on the friction surface are carried away and washed away by the flow and circulation of oil, achieving good lubrication, reducing friction, lowering wear and tear, reducing the consumption of vulnerable parts, reducing power consumption, and extending the service life of equipment. However, the maintenance and management of the centralized lubrication system are quite complex, and adjustments are also difficult

Any problem at any stage may cause the entire lubrication system to malfunction or even shut down. So it is necessary to continuously improve in future production practices.

In the entire lubrication system, various lubrication equipment and devices, control devices and instruments are installed to regulate and control the flow rate, pressure, temperature, impurity filtration, etc. in the lubrication system, making equipment lubrication more reasonable

In order to ensure the safe and reliable operation of the entire system, the following automatic control and signaling devices should be installed.

1. Host startup control

Before starting the host, the lubricating oil pump must be started to supply oil to the host. The main engine can only be started when the oil pressure is normal. If the oil pressure fluctuates greatly or cannot rise after the lubricating oil pump is started, it indicates that the lubrication system is abnormal. At this point, even if the operation button is pressed, the host cannot rotate, which is a necessary safety protection measure. There are many methods for controlling interlocking, usually by installing oil pressure relays on the oil pressure pipeline to control the electrical circuit of the host operation.

2. Automatically start the oil pump

In the lubrication system, if the system oil pressure drops below the working pressure (0.05MPa), the standby oil pump will start and issue a warning signal at the same time. The red light will turn on and the electric horn will sound. At this time, the on duty personnel will immediately inspect and take measures to eliminate the fault based on the warning signal. After the system oil pressure returns to normal, the standby pump will stop working.

3. Forcefully stop the host from running

After the standby oil pump is started, if the system oil pressure continues to decrease (below the working pressure) (0.08~1.25MPa), the oil pump will automatically stop running and send a signal; Force the host to also stop running, while issuing an accident alarm signal, with a red light on and an electric horn sounding.

4. High voltage signal

When the working pressure of the system exceeds the normal working pressure of 0.05MPa, a high pressure signal should be issued, the green light will turn on, and the electric horn will sound. The on duty personnel should immediately inspect and eliminate the malfunction.

Starting the backup oil pump and forcing the main engine to stop are often controlled using electric contact pressure gauges and pressure relays.

5. Oil level control of fuel tank

The oil level control of the fuel tank often adopts a float type liquid level controller with a reed switch. When the oil level in the fuel tank continuously drops to the lowest allowable level, the contact of the liquid level controller closes, sends a low liquid level warning signal, the red light lights up, the electric horn sounds, and forces the oil pump and the main engine to stop running. When the oil level in the tank continues to rise (possibly due to water or other media entering the tank) and reaches the highest oil level, a high level warning signal will be issued, the red light will light up, and the electric horn will sound. Immediate inspection and limiting measures should be taken to eliminate the fault.

6. Fuel tank heating control

When working in cold regions or winter, the lubricating oil in the oil tank should be heated, and the temperature of the lubricating oil is generally maintained at around 40 ° C to maintain the fluidity of the oil. Otherwise, the control of the entire system will be difficult due to low temperature and increased oil viscosity. There are two methods of heating, one is to use steam heating, which is relatively gentle; Another method is to use electric heating elements for heating. The latter heating method is more intense and sometimes causes thermal cracking reactions in the oil, reducing viscosity and generating gum precipitates. Both methods are equipped with automatic temperature adjustment devices, which automatically cut off power or steam when the oil temperature reaches the specified temperature.

7. Automatic temperature measurement device of the system

The temperature of relevant parts in the system needs to be measured regularly during operation in order to grasp the operating situation. The oil and water temperatures of the fuel tank, oil drain pipe, inlet and outlet coolers must be measured at all times. For this purpose, an automatic temperature measurement device was adopted. The commonly used measuring devices are thermistors and bridge thermometers, which can measure the temperature of various parts by simply twisting the conversion switch on the operation panel.

8. The filter automatically starts

When the pressure difference between the oil flowing in and out of the filter is greater than 0.05~0.06MPa, the filter is blocked. The filter should be automatically activated to remove impurities around the filter cartridge in the disc filter. Usually controlled by an electric contact differential pressure gauge, when the pressure difference decreases (or returns to the allowable pressure difference range), the power is cut off and the filter cartridge cleaning and scraping are automatically stopped

There are also two types of lubrication systems included in the centralized lubrication of thin oil:

1. Centralized circulation lubrication system for rotary piston pump oil supply

2. Circulating lubrication system for gear oil pump oil supply

中文

中文 英语|English

英语|English 法语|France

法语|France 印度语|San

印度语|San