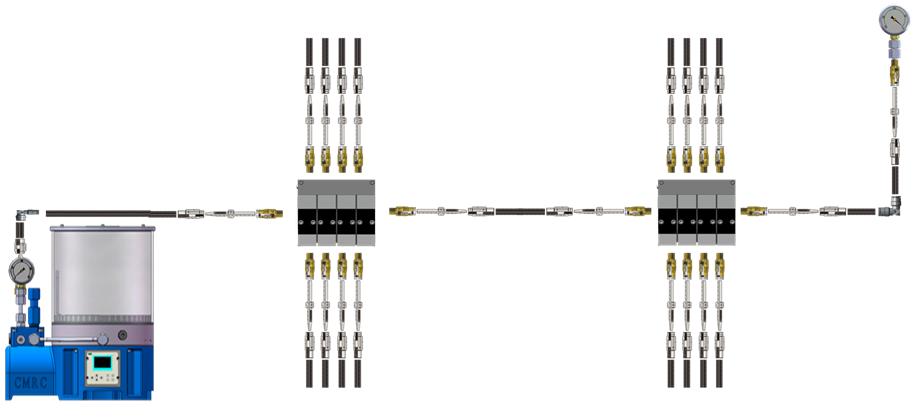

Single line lubrication system: Principle: There is only one main line, usually injected with lubricant by a plunger pump into the main line, and directly distributed to each lubrication point through a single line oil feeder. After the plunger pump stops working, the single line oil feeder resets, the return valve opens, and some of the grease in the pipeline is returned to the oil barrel of the plunger pump. When a single lubrication point malfunctions, it will not affect the oil supply of other lubrication points. The flow sensor will feedback the oil supply signal of each point to the control system and display it on the human-machine interface.

|

system parameter

|

|||

|

model

|

QRH-2

|

rated voltage

|

DC24V/AC220V/AC380V

|

|

nominal pressure

|

31.5Mpa

|

capacity

|

6/8/10/12/16L

|

|

internet traffic

|

10/30/235 ml/min

|

Control points

|

1-50 o'clock

|

|

Controlling Distance

|

1-30 meters

|

protection grade

|

IP55

|

|

operation temperature

|

-30 + 85℃

|

Storage Humidity

|

-40 + 85℃

|

|

Working humidity

|

10% to 90%

|

Storage Humidity

|

5% to 90%

|

|

Applicable lubricating grease

|

|||

|

Suitable for thin oil, NLGI 2 # and below oils, and can be used for NLGI 3 # oils under specific conditions (such as high temperature).

|

|||

|

Lubrication point status detection

|

|||

|

Monitor the oil output signal of each lubrication point

|

|||

|

Function (optional)

|

|||

|

■ Network detection ■ Large capacity ■ Single fuel supply time control ■ Single fuel supply quantity control

|

|||

|

Function Introduction

|

|||

|

The single line lubrication system is controlled by a lubrication pump to supply oil to the single line oiler. When any lubrication point is blocked, it will be displayed on the human-machine interface. The lubrication system can set the working cycle (up to 9999 hours and 9999 minutes) and oil supply amount

|

|||

|

Application

|

|||

|

Lubrication points are relatively few and concentrated within a small radius, and lubrication sites with strict oil supply requirements

|

|||

|

scope of application

|

|||

|

Mining machinery, engineering machinery

|

|||

中文

中文 英语|English

英语|English 法语|France

法语|France 印度语|San

印度语|San