Overview of ZDRH Intelligent Centralized Lubrication System

Due to the continuous development of modern electrical control technology and computer communication technology, the automation level of China's industrial development is constantly improving. Some new technologies, processes, and equipment have been widely applied in industries such as steel, metallurgy, and aluminum.

Traditional lubrication equipment cannot adapt to modern lubrication operations, and for important equipment and machinery, it cannot achieve the lubrication effect that enterprises want to achieve. Its lubrication efficiency also fails to meet the expected standards, resulting in wear and damage to mechanical equipment. In order to maintain the service life of existing equipment, improve the production capacity of equipment and machines, and ensure safe and reliable production, we must continuously improve the equipment operating rateImprove the lubrication performance of lubrication equipment. The emergence of new intelligent lubrication equipment will be more conducive to the protection and operation of the equipment, and will be more conducive to the development of modern industry.

The ZDRH intelligent centralized lubrication system is a high-tech product developed by Beijing MCC Huarun Technology Development Co., Ltd. This intelligent lubrication system integrates precise oil quantity control, timed lubrication, intelligent display, remote monitoring, and control based on the lubrication requirements and standards of modern enterprises for machinery and equipment. Entering the era of intelligent control and network monitoring for lubrication operations. This intelligent device fully utilizes programmable logic controllers (PLCs)PLC technology provides detailed records of the location and cause of faults, and prompts maintenance personnel to perform correct operations through the human-machine interface (HMI) and upper computer. Realize the intelligence of centralized lubrication system. This intelligent lubrication equipment adopts the world's most advanced volumetric metering technology to continuously measure the amount of liquid oil. Based on user feedback and the on-site lubrication environment, our company has made overall improvements to the existing lubrication equipment, making the working performance of the intelligent lubrication equipment more reliable and the lubrication effect more obvious. The improved intelligent device combines sensors, information control, automation, mechanical manufacturing and other technologies, which can achieve timed, quantitative, and fixed-point lubrication, with real-time monitoring, intelligent communication, fault self checking, and alarm functions.

The various lubrication points of the intelligent lubrication system are independent, allowing the oil supply and interval period of each lubrication point to be adjusted arbitrarily on the touch screen,The ZDRH intelligent centralized lubrication system has the following characteristics:

1) Planned oil supply: not affected by environmental conditions, able to supply oil according to the planned quantity and save lubricating oil.

2) Reducing expenses: Not only can it save lubricating oil and labor, but it can also save labor and extend equipment life due to the low friction of bearings.

3) Improve equipment operation rate: Due to the implementation of ideal oil supply, lubrication failures of the equipment have been prevented.

4) Efficient oil supply: It can automatically and accurately supply oil in a short period of time, achieving oil supply without any leakage points.

5) Preventing lubricant degradation: From the oil pump to the refueling point, the lubricant should not come into contact with external air, thus preventing lubricant degradation and the mixing of impurities.

6) Preventing danger: It can safely supply oil during equipment operation and also supply oil to high places, dangerous areas, and harsh environments, preventing potential personal accidents during oil supply operations.

Since its launch on the market, this intelligent lubrication system has been widely used in sintering machines, grate coolers, steel mills, continuous casting machines, ring coolers, stacker reclaimers, heavy-duty plate machines, large excavators, dump truck heavy-duty rollers, vibrating screens, large cranes, guide rails (wheels), shakers, high-speed lines, roller drills, electric shovels, and other places where lubrication points are concentrated, environments are harsh, and it is difficult or impossible to refuel manually.

Components and operating parameters of ZDRH intelligent centralized lubrication system

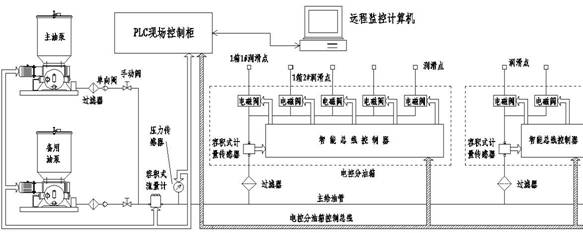

The entire intelligent lubrication system includes: control system, power system, oil supply system, detection system, and system pipeline network. Each part works in coordination, and the functional role of each part is very important in the entire intelligent lubrication system. The composition of the intelligent lubrication system is as follows:

2.1 Control System

The integrated main control cabinet adopts the original Siemens from GermanyThe S7-300 PLC, as a controller, has a Chinese text display function. Users can obtain relevant lubrication information through the information on the touch screen or text display, and can accurately obtain the fault situation during lubrication operations. This control system can comprehensively coordinate the operation status of various parts of the system and monitor the system's operation status in real time. The ZDRH intelligent centralized lubrication system uses configuration control technology to display the actual lubrication situation at each lubrication point through the monitoring screen of the upper computer, and can monitor whether there are any faults in the lubrication operation points.

The required working parameters for the main control cabinet are: communication220V voltage and 6.5KW power.

2.2 Power system

This intelligent lubrication system is powered by a high-pressure oil pump to supply oil to the entire lubrication system. The power oil pump can be infinitely regulated. The power system is located in the main control cabinetPLC control. Users control the working status of the oil pump through PLC. When performing lubrication operations, a high-level signal is sent to the high-pressure oil pump to start the high-pressure oil pump for operation. The ZDRH intelligent lubrication equipment is equipped with two oil pumps for lubrication operations, which serve as backup for each other. The switching between the two oil pumps is controlled by a PLC program. The intelligent lubrication equipment is also equipped with a replenishment pump for two high-pressure oil pumps, which automatically replenishes the low-pressure oil pump with low liquid level.

The required operating parameters for the power system are:0-40MPa pressure, AC 380V AC voltage, 3.0KW power (including the power of the oil replenishment pump).

2.3 Oil supply system

The lubrication system using solenoid valves as oil supply components is based on the principle that solenoid valves are connected between the oil supply pipe and the lubrication pointFrom the positive direction of the oil feeder, a flow sensor is installed on the left side of the solenoid valve group, and a PLC is used to control the opening and closing of the solenoid valve while detecting the status of the flow sensor. In this system, adjusting the amount of oil (grease) added to the lubrication point is achieved by adjusting the switching on time of the solenoid valve. Each lubrication point canAutomatic refueling with "timed and quantitative" function, the system can detect blocked solenoid valves and directly indicate the number of the electronic fuel distribution tank where the solenoid valve is located. The use of quantitative measurement fundamentally solves the problem of inaccurate measurement of heavy oil. Users can specify the amount of lubricating grease to be added to each lubrication operation point. Once the system timer is set, it will automatically start and stop automatically after adding the specified number of milliliters. The entire intelligent lubrication system allocates the appropriate amount of oil to the oil system and lubricates the lubrication points that need to be operated point by point. The amount of oil lubricated at each point, the oil supply cycle, and the lubrication cycle of the entire lubrication group can be set on the touch screen or text display of the main control cabinet.

The required working parameters for the oil supply system are: communication220V voltage, 24V DC voltage, 60W power.

2.4 Detection System

There is a weighing sensor at the base of the ZDRH intelligent centralized lubrication oil pump supply system,PLC detects the oil supply status of each point through quantitative and flow sensors, combined with signals from other sensors, making the PLC's fault detection and judgment of each point more reliable. PLC outputs fault alarm and fault location, and displays its fault content through touch screen.

2.5 System Pipe Network

The high-pressure grease pipeline and addressing cables used for control and detection have a simple and reliable addressing method that makes control and detection simple and flexible. Greatly reduce the difficulty of maintenance.

Working principle of ZDRH intelligent centralized lubrication system

When the system is working, the main control cabinet first outputs a signal to activate the high-pressure oil pump, which delivers the grease to the oil pipeline (delaying the pressure rise for a few seconds to increase the pressure of the oil pipeline). The main control cabinet outputs a signal to open the solenoid valve of the first lubrication point to supply oil to the first lubrication point. At this time, the solenoid valves of other lubrication points are closed, forming an oil delivery path from the high-pressure oil pump to the first lubrication point. The pressure of the oil pump is all concentrated at this lubrication point, which ensures the oil supply pressure at that point and also ensures the oil supply at that point; The oil supply of the lubrication point is achieved by adjusting the oil supply of the point, which is accurate and reliable, and can be adjusted through the keyboard. When the oil supply process of the first lubrication point is completed, the main control cabinet outputs a signal to close its solenoid valve, and at the same time opens the solenoid valve of the second lubrication point to supply oil to the second lubrication point. The process is the same as the oil supply process of the first lubrication point. When the oil supply process of the second lubrication point is completed, the control system closes its solenoid valve and opens the solenoid valve of the third lubrication point... and so on. The system supplies oil to all lubrication points point by point. When the oil supply of the last lubrication point is completed, the system enters the cycle time (the interval between two system operations), and the high-pressure oil pump stops working. The cycle time of the lubrication system can also be freely set. When the set cycle time is reached (i.e. the interval timer ends), the system will restart and repeat the process of supplying oil for the first time. This process is repeated to achieve intelligent lubrication of the main equipment.

The actual designed program divides the lubrication points of the system into four groups, and the cycle time of each group is individually adjustable, and the oil supply of each lubrication point is also individually adjustable.

The high-pressure oil pump inlet and outlet of the fully automatic lubrication system are equipped with filters to ensure the purity of oil and grease in the oil circuit and reduce system oil supply failures. The high-pressure oil pump is equipped with an electric fuel pump to replenish grease to the oil storage cylinder of the high-pressure oil pump. The oil storage cylinder of the high-pressure oil pump is equipped with upper and lower limit limiters, which are interlocked with the fuel pump. When the oil level of a certain high-pressure oil pump is below the lower limit, the fuel pump automatically starts to replenish the pump, and when the oil level reaches the upper limit, the fuel pump automatically stops replenishing. Usually, two high-pressure oil pumps are used as backups for each otherPLC coordinated control. When the working pump fails to start within the set time or fails to establish oil pressure after starting, the control cabinet will output an alarm and start the standby pump.

The external interfaces of the lubrication system are all passive contacts, which can be interlocked with the upper computer in the main control room of the factory to remotely monitor the working condition of the lubrication system and achieve synchronous start stop of the lubrication system and the main equipment. Fault inquiry can be conducted through a text display.

中文

中文 英语|English

英语|English 法语|France

法语|France 印度语|San

印度语|San